Hose Management

Hose assemblies are used in almost all hydraulic devices and systems. Hydraulic hoses are subject to constant wear due to a wide variety of influences. These influences include, for example: Pressure pulses, mechanical damage, solar radiation, or high temperatures.

To ensure safety and minimize downtime of your equipment, you must inspect and replace hose assemblies at regular intervals. Hose assemblies at plants are classified as work equipment according to the Industrial Safety Regulation.

Guide values for the maximum service life of hose assemblies according to BGR 237:

| Hose assembly requirements: | Recommended replacement intervals: |

| Normal requirement | Maximum 6 years (operating life, including max. 2 years storage time) |

| Increased requirement due to: strong external/internal influences, or increased operating times | 2 years operating life |

We as Siebert – Hydraulics & Pneumatics take over the topic of hose management in your company as a specialist company for hose assemblies of all kinds. The aim of hose management is to reduce downtime in your company, to ensure safety at the workplace and to relieve your staff.

Our services include:

– Performing a risk and hazard assessment

– Manufacture, installation and commissioning of hose assemblies

– Disposal of old/defective hose assemblies

– Preparation of the necessary documentation

– Regular inspections

– Reminders of inspection intervals

– Replacement of hose assemblies in the shortest possible time

– Parker Tracking System

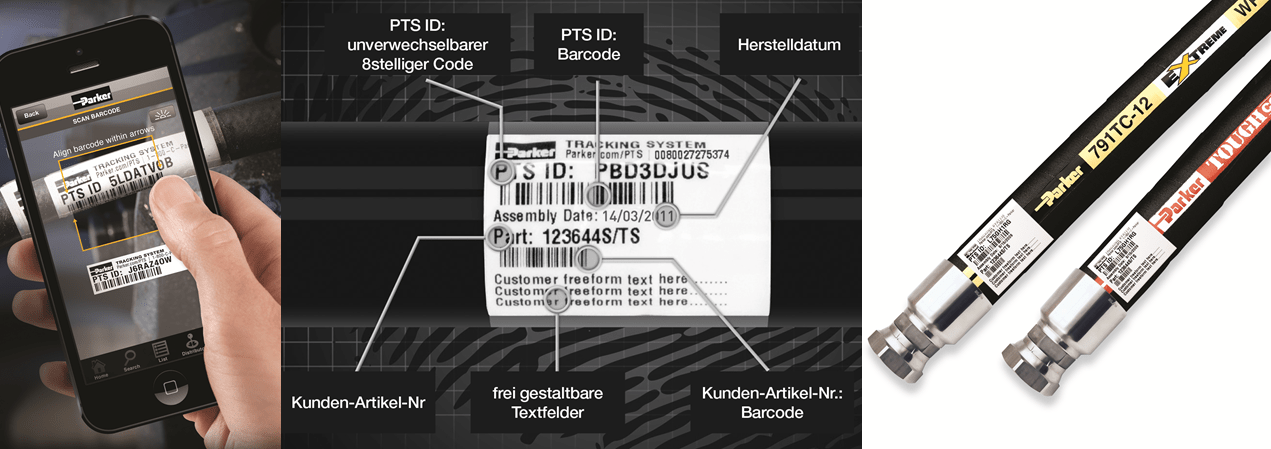

Our hose management is supported by the Parker Tracking System, the most advanced and comprehensive system of its kind on the market.

The Parker Tracking System is an innovative hose management software with worldwide access for all Parker dealers, as well as the unique identification of each individual hose assembly.

For more detailed information, click here: Parker Tracking System